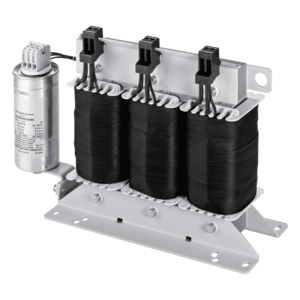

All-pole sine filter

SFA 400/16,5

Characteristics

Benefits

› Prevention of overvoltages on the motor

› Long cable lengths possible

› Reduction in motor noise

› Minimisation of bearing currents

› Minimisation of leakage currents (is beneficial in the event of incorrect RCD tripping)

› Reduction in line-borne and field-borne emitted interference: can be omitted from shielded cables, where necessary

› Reduction of motor losses

| Product | All-pole sine filter |

| Order number | SFA 400/16,5 |

| Series | SFA |

| Inductance | 3x 2.4 mH |

| Rated current | 3x 16.5 Aac |

| Linear current | 3x 24.75 Aac |

| Rated voltage range | 0 V to 480 V |

| Rated voltage | 400 V |

| Phases | 3 |

| Frequency range | 5 Hz to 60 Hz |

| Switching frequency range | to 16 kHz |

| Motor or converter power | 7.5 kW / 10.06 HP |

| EN Insulation class | H (180°C) |

| UL Insulation class | class 180 |

| Duty Cycle | 100 % |

| Power loss | 137.00 W |

| Wire material | Copper |

General

| Duty Cycle | 100 % |

| Cooling type | AN |

| Switching group | III0 |

Environment

| Ambient temperature | -10 °C to 45 °C / 14 °F to 113 °F |

| Max. installation height | 1,000 m / 3,281 ft |

Protection and Safety

| Protection type | IP 20 |

| Protection class (prepared) | I |

| Degree of contamination | 2 |

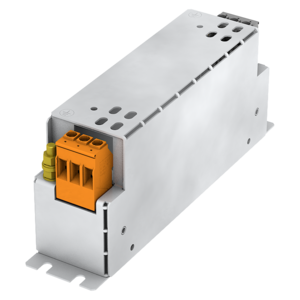

Electrical Connections

| Input terminal | Screw terminal |

| Output terminal | Screw terminal |

| Terminal PE | Bolt connection |

Size and Weight

| Width | 320 mm / 12.6 in |

| Height | 200 mm / 7.87 in |

| Depth | 135 mm / 5.31 in |

| Weight | 17.5 kg / 38.581 lbs |

| Low Voltage Directive | EN 61558-2-20 |

| RoHS compliant | EN IEC 63000 |

| Approval cURus - Recognized | UL 508; CSA 22.2 |