The requirements of modern systems and plants are becoming more and more complex through increased amounts of power and microelectronics. BLOCK provides a comprehensive range of reactors and filters here in order to guarantee reliability, efficiency and freedom from interference, including within the framework of Industry 4.0. The range includes filtering of harmonic distortions and high-frequency conducted and radiated interference emissions. The use of Power Quality products protects motor insulation and increases system efficiency by reducing leakage currents.

RESEARCH AND PRODUCTION COMBINED AT ONE LOCATION

A high level of vertical integration in production and many years of knowledge and expertise in filtering for frequency inverters for drive systems through our in-house Research and Innovation Center guarantee the best practice EMC solution for our customers’ applications.

Power Quality winding materials from BLOCK can be produced with Future Winding technology. This enables maximum power density through optimum cooling effects in compact spaces.

FREE FROM INTERFERENCE

The use of BLOCK Power Quality products optimizes interference immunity for drive systems. Ensuring a connection between components free from interference is a prerequisite for flawless operation of the overall drive system for communications systems in Industry 4.0 in particular.

RELIABLE

Power Quality solutions from BLOCK enable significant increases in the drive system’s reliability. They guarantee a clean design for the filtering for the frequency inverter. Reactors and filters developed in accordance with the latest research findings and production technology are characterized by their quality and durability.

EFFICIENT

BLOCK products are made in accordance with the highest quality criteria based on pioneering technology and on our more than 80 years of experience in research, development and production. Our reactors and filters in particular feature optimized performance and compact designs and provide the most efficient solution to meet customers’ requirements.

LIQUID COOLING FOR USE IN CLOSED SYSTEMS

Compact machine, plant and control cabinet systems often do not have much room for an effective cooling system. We have developed a reactor for AFE inverters with liquid cooling in our Development Center using analytical and thermal simulations for this type of enclosed space. The premium quality materials used and our in-house production technology have resulted in a compact product for our customers featuring low losses despite the high frequency ripple.

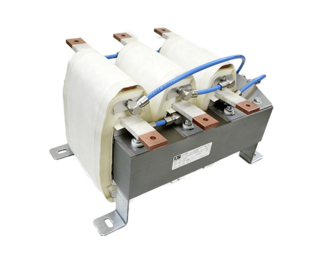

ALL-POLE SINE FILTER SF4

All‑pole sine filters from the SF4 series combine all of the benefits of Future Winding technology. They allow unshielded motor cables to be used and optimize the drive’s EMC performance overall. Common mode currents are reduced with this while leakage currents are also minimized. The SF4 products from BLOCK improve the cooling effect and achieve lower proximity losses thanks to the latest winding and production technologies combined with the latest scientific findings. This ensures that their performance is optimized in particular compared with similar sine filters on the market.